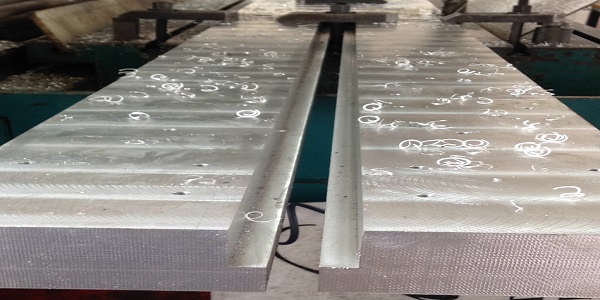

Aluminium rotary die board

Aluminium rotary die board

Aluminum mold to produce rotary die boards. The vertical pressure on the molds only to move also the two side mold sectors for the undercut. Heated by longitudinal holes for the passage of the liquid from centralized system.The lateral doble mechanism of inclined sliding in steel,bronze and castiron , suport them and produce the lateral pressure to two molds sector .The vertical pressure is transmitted to the horizontal one optimally without anomalies and excessive dispersions. The mold has the characteristic of great reliability as humidity is irrelevant in the process.The structure has been engineer for a long life with little maintenance. By mold robustness it can work with pressures ranging from minimun 7 to 20Kg/cm2 to better uniform the thickness of the wood also. Moreover in the mold there are some stainless slabs with rapid relocation The mold and the inserts are equipped with end stops. The drying of the sheets is gradual and uniform.The molded pieces always falls within the tolerances of thickness and linearity ..